In the wastewater treatment process, chemical dosing is a crucial step in ensuring water quality meets standards and achieving optimal treatment results. The integrated dosing device, as a new type of equipment, is gradually becoming an important tool in the field of wastewater treatment due to its efficiency, automation, and precision.

So, how does an integrated dosing device improve wastewater treatment efficiency?

1. What is an Integrated Dosing Device ?

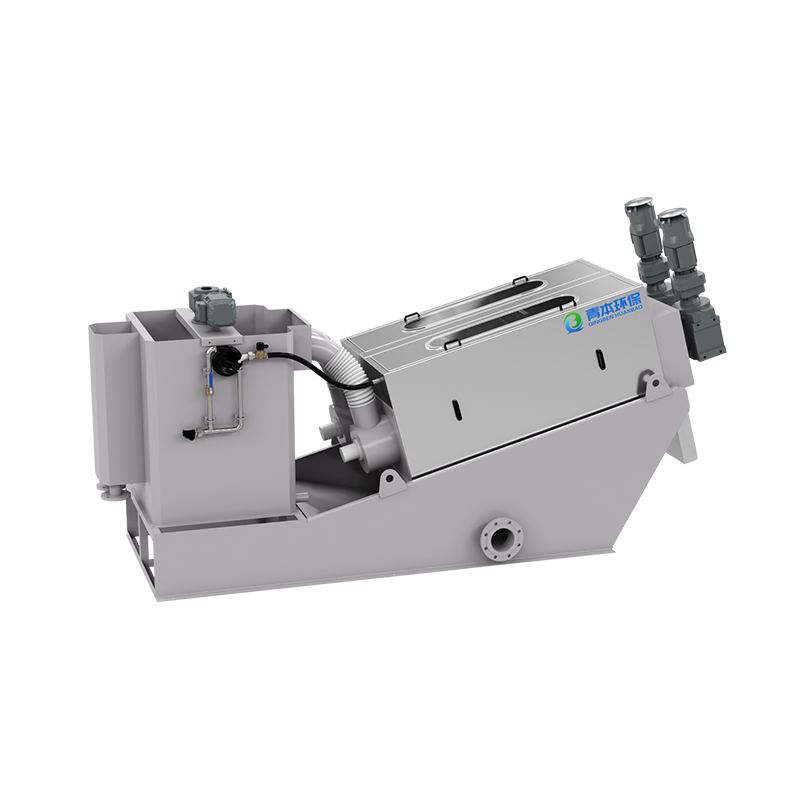

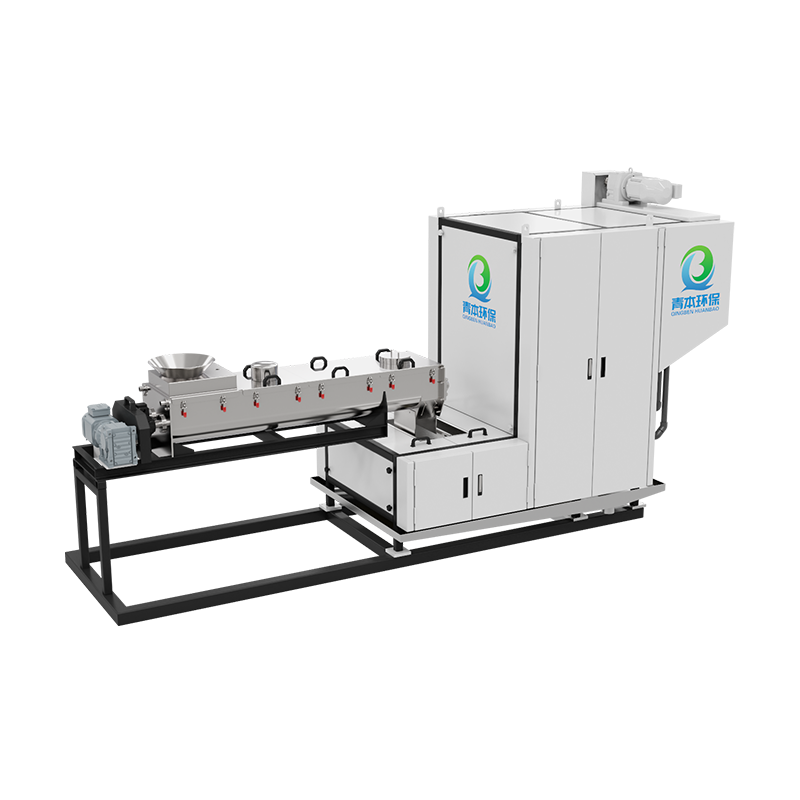

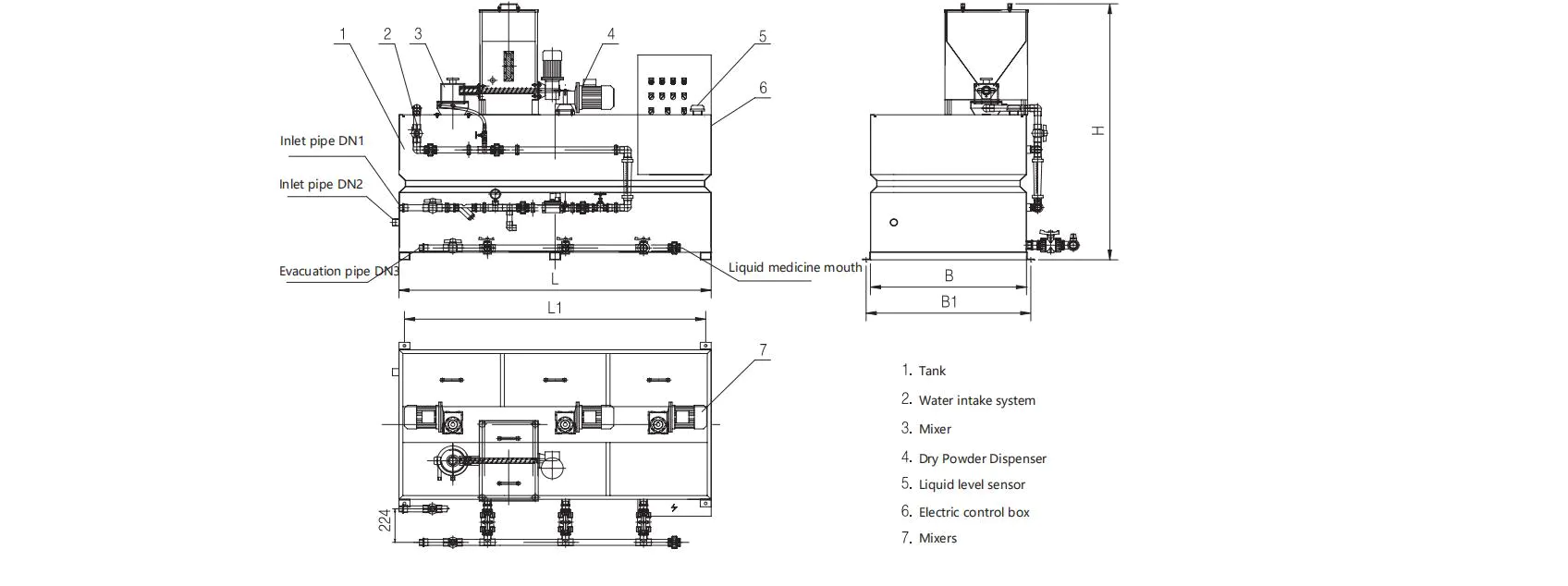

An integrated dosing device is a piece of equipment that integrates multiple functional modules such as chemical storage, transportation, metering, and control. It is widely used in chemical dosing in wastewater treatment. Compared with traditional decentralized dosing systems, integrated dosing devices are more compact, easier to operate, and can achieve automated control. Its core function is to precisely control the amount, time, and concentration of chemicals added, ensuring the optimal use of chemicals in the wastewater treatment process.

2. Working Principle of an Integrated Dosing Device

The working principle of an integrated dosing device mainly relies on its highly integrated functional modules, ensuring accurate chemical delivery and efficient mixing. It typically includes the following main steps:

Chemical Storage and Transportation

The integrated dosing device is equipped with a chemical storage tank, and the chemicals can be automatically transported to the dosing system through pipes. According to the needs of wastewater treatment, the device can automatically adjust the transportation volume to ensure a sufficient supply of chemicals.

Precise Metering and Dosing

Through dosing pumps and flow meters, the integrated dosing device can precisely control the amount of chemicals added. The system automatically adjusts the chemical dosing rate according to the water quality and treatment requirements, ensuring the precise use of chemicals.

Automatic Control System

The integrated dosing device is equipped with an intelligent control system that can automatically adjust the amount and timing of chemical dosing based on real-time monitoring data. The control system can also automatically calibrate the system according to preset treatment standards to achieve optimal treatment results.

Real-time Monitoring and Feedback

The monitoring system of the integrated dosing device can provide real-time feedback on the chemical dosing situation, including key parameters such as chemical concentration, dosing amount, and flow rate. This allows operators to understand the system status in a timely manner and intervene in case of abnormalities.

3. Advantages of Integrated Dosing Systems in Improving Wastewater Treatment Efficiency

Improved accuracy of chemical dosing, reducing waste

Integrated dosing systems can automatically adjust the chemical dosage based on real-time data such as pollutant concentration and flow rate in the wastewater. This ensures more precise chemical usage, guaranteeing treatment effectiveness while avoiding overuse or underdosing, thus reducing resource waste and unnecessary costs.

Automated control, reducing manual intervention

Traditional dosing systems often rely on manual operation to adjust chemical dosage, which is susceptible to human error. Integrated dosing systems feature automated control functions, allowing for automatic adjustment based on set parameters, reducing manual intervention and the risks associated with human error. This improves operational stability and reduces the workload of operators.

Real-time monitoring and feedback, improving response speed

Integrated dosing systems are equipped with intelligent monitoring systems that can monitor various data during the chemical dosing process in real time and make dynamic adjustments. Through remote control and alarm functions, the system can quickly respond to abnormal situations and adjust the chemical dosage in a timely manner, ensuring the continuity and stability of the wastewater treatment process.

Optimized chemical usage, reducing costs

Integrated dosing systems can automatically adjust the amount of chemicals used based on changes in wastewater quality, avoiding chemical waste. Through precise dosing, it effectively reduces chemical procurement and usage costs, while improving the overall operational efficiency of the wastewater treatment plant.

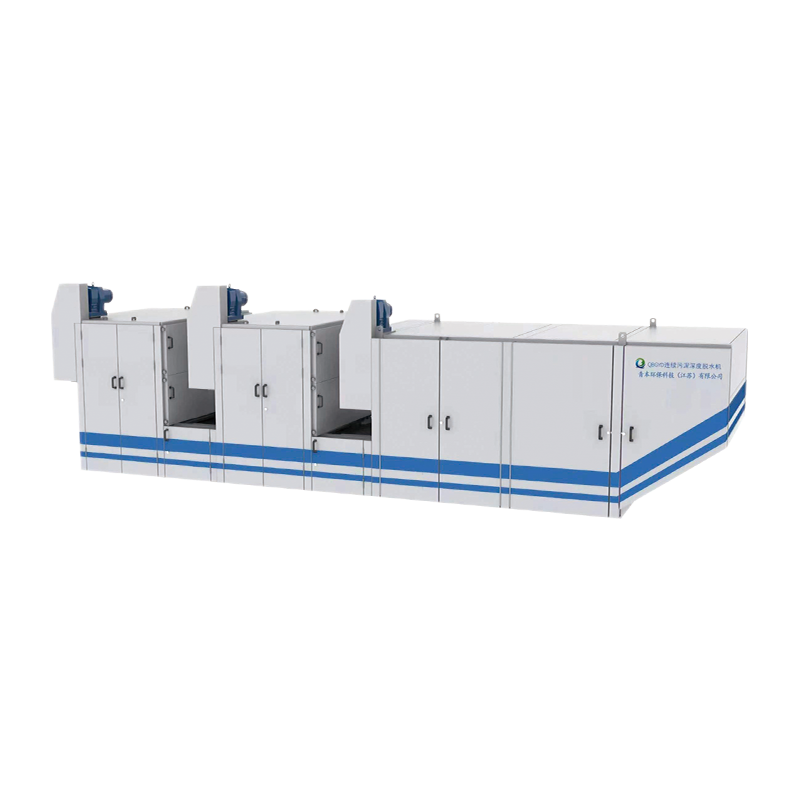

Improved system stability and reliability

The high degree of integration of the integrated dosing system makes the entire system more compact, reducing connection problems between components in traditional systems and lowering the probability of system failures. The high reliability of the equipment ensures that chemical dosing remains stable throughout the wastewater treatment process, reducing equipment failures and downtime.

4. Applications of Integrated Dosing Systems in Wastewater Treatment

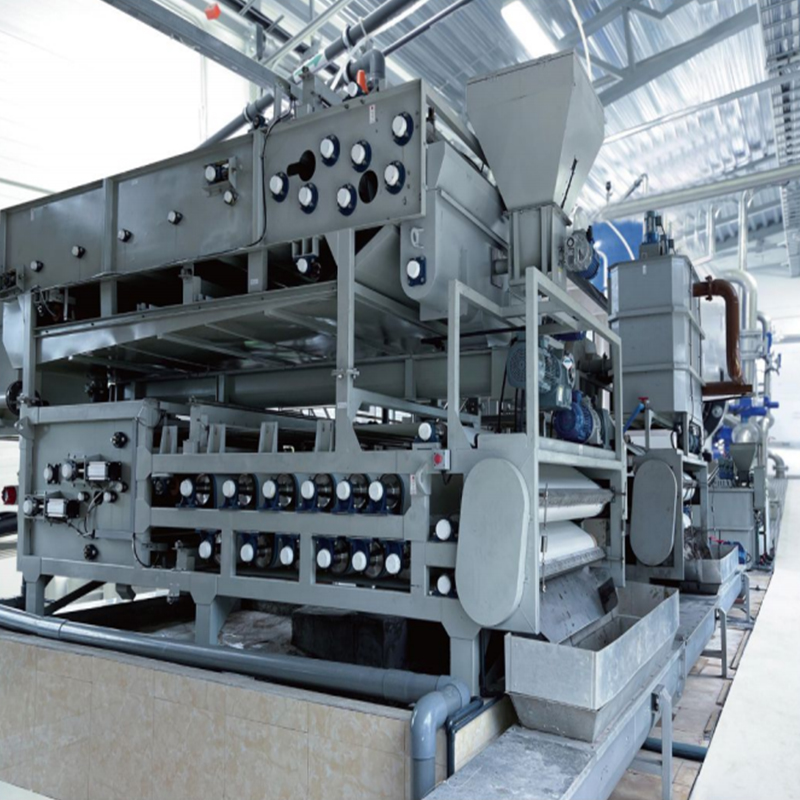

Integrated dosing systems are widely used in various wastewater treatment plants, especially in situations requiring precise control of chemical dosage. Specific application scenarios include:

Municipal wastewater treatment

Municipal wastewater treatment usually involves large-scale water treatment, requiring stable and precise chemical dosing. Integrated dosing systems can adjust the chemical dosage based on real-time water quality data, ensuring that the water quality meets discharge standards while avoiding chemical waste. Industrial Wastewater Treatment

Industrial wastewater often contains various toxic and harmful substances, making the accuracy of chemical dosing crucial. Integrated dosing systems can precisely adjust the amount of chemicals added, helping to treat complex wastewater components and ensuring that the final discharged water quality meets environmental requirements.

Water Treatment Plant Disinfection

In the disinfection process of drinking water plants, integrated dosing systems can adjust the amount of disinfectant added in real time according to water flow and water quality, ensuring the safety and hygiene of the water source.

Water Purification

In the water purification process, the amount and proportion of chemicals added are crucial to the purification effect. Integrated dosing systems, by precisely controlling the chemical dosage, can ensure that the water quality meets standards and reduce the workload of operators.

As an important piece of equipment in wastewater treatment, integrated dosing systems improve the efficiency and stability of wastewater treatment through automated control, precise dosing, and real-time monitoring. They not only reduce chemical waste and operating costs but also improve system reliability and ensure that water quality treatment meets standards.